LED switching, control

LED - Energy savings with a bright future and a few hiccups

Sales of LED light sources have grown rapidly in recent years, thanks to improvements in efficiency and colour rendering factor. There is hardly a lighting sector where they are not present: traditional incandescent (retrofit) versions are the preferred choice in place of energy-saving (fluorescent) bulbs. Their banded illumination range is well suited to any age and opens up new possibilities in lighting design. Even high-power stage and studio spotlights have LED versions.

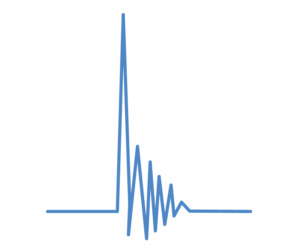

However, not all light bulbs can be replaced by LED retrofit light sources. This is due to their short but extremely high starting currents, which can be up to a thousand times the rated current, causing the switch contact/relay to burn out or the fuse protecting the circuit to blow.

The challenges of LEDs and how to deal with them

There are general guidelines for LED lamps, such as their socket size, luminous intensity and electrical consumption, but no guidelines for other important factors. Compared to a conventional tungsten filament bulb, an LED lamp contains electronics for control, the layout and design of which is determined by each manufacturer. Manufacturers of switching and dimming devices currently do not receive any indication from the light source manufacturers as to which electronics control which and how they affect the operation of the bulb.

If there are no standards and regulations, we have to test!

If the switching load is not indicated on LED lamps or discharge lamps, it must be assumed that the product has not yet been tested for this parameter. At the same time, the specifications for the load are not always very informative. What exactly is the switching current specified by the LED lamp manufacturer? As this can vary from bulb to bulb, we need to take due care when calculating.

Therefore, to determine the load characteristics, Theben performs continuous measurements with all light sources. During these tests, the switching devices are subjected to at least 40,000 switching cycles in order to obtain reliable results for the switching loads.

LED - The executioner of switch contacts

Low consumption in use, but wasteful with every power-up

An everyday example: in the stairwells of a large residential building, maintenance staff are replacing the lighting with conventional LED lamps. The lighting is replaced by replacing old light fixtures in large high-rise buildings. The savings potential is only promising if, in addition to the direct benefits in terms of energy consumption, long life can be guaranteed, of course with lower maintenance costs.

But from one day to the next, the staircase vending machines fail. An investigation showed that the switch contacts were burnt out from overloading, although the rated power was significantly reduced with the new installation.

Capacitive loads are stressing the switching contacts

How is it possible for a few watts of LED light to destroy a switch contact designed for a much higher load? On closer inspection, the answer lies in the switching current. In a conventional filament, the switching current is ten times the rated current. In LED and energy-saving lamps with capacitive characteristics, this value is typically more than a thousand times the rated current for up to a few microseconds. Our VDE-certified test laboratory has shown that in the worst case, the switching current of a 1.8 W LED lamp can be 19 A, which is 1706 times its rated wattage.

Attention! Attention!

Shutdown warning

We would like to draw your attention to the problem of the shutdown warning (two flashes before shutdown according to DIN 18015-2).The shutdown warning is equivalent to a fast on-off switch in terms of technology and its mechanism of action on the electronic ballasts and the charged capacitors in the LEDs, and therefore has a direct negative impact on the life expectancy of the devices.

How to switch LED lights

With the right switch contact at the right moment

Two switching contacts: tungsten pre-contact

For switching high currents, special switching contacts are required: silver-oxide-on-oxide (AgSn0,). Theben uses a combination of two contacts in series: the tungsten pre-contact. The pre-contact contains high ohmic resistance and high hardness tungsten, which can withstand high starting currents and also acts as a current limiter, so that the low resistance main contact is relieved of switching currents. Theben uses these relays in its TR 609 top2 S and SELEKTA 175 top2 digital time switches, as well as in theLUXA P motion sensors and theRonda P presence detectors.

Precise coupling at a certain point:

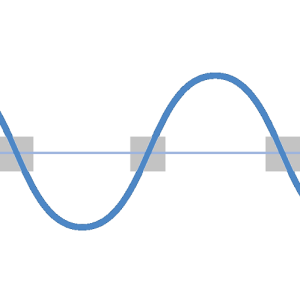

zero transition coupling

Switching devices designed for switching C-type loads are generally better able to withstand high switching currents, and to this end Theben uses an efficient solution called zero-point-transition switching. This solution switches at the zero-point transitions of the AC sine wave, where the effect of the switching current surge is minimal, thus protecting the relay contact and increasing its lifetime even under high switching loads. Almost all top2 series, theluxa S motion sensors and PlanoCentro presence detectors use this solution.

Environmentally friendly and safe connection:

Cadmium-free contacts

Cadmium oxide was considered to be a suitable material for high switching current contacts. Until we want to comply with the RoHS directives - which place certain restrictions on the material of switching contacts.

In the Millennium year, Theben therefore switched to the more environmentally friendly AgSno, an alloy with equally good, and in some cases even better, parameters such as higher burnout resistance or better ageing resistance to electrical conductivity and significantly reduced electrochemical migration during DC operation.

Control the brightness of LEDs?

It cannot be taken as cash!

Dimmable or not?

It depends on the right choice.

Not all LED lamps are dimmable. Even dimmable versions have widely varying dimming characteristics depending on the manufacturer. LEDs often flicker and it is impossible to control them linearly and harmonically, as electronic ballasts respond very differently to phase- and flicker-controlled regulation. Some manufacturers therefore only allow one of these methods.

Continuous lighting is not desirable.

Leakage current is also sufficient.

The other problem is caused by the dimmer's noise filter capacitors, whose continuous leakage currents are sufficient to bend a 1-2 Watt LED lamp, making it impossible to switch them off completely.

Dimmer compatibility with LED lamp?

It depends on the right choice.

For stepless control, not only the LED lamp must be dimmable, but also the dimmer must be LED compatible.

Theben has developed several solutions for this purpose:

- Pre-defined settings for different LED lamps

- Dimmer curves can be uploaded via ETS

Control the brightness of LEDs?

With Theben it is possible!

Depends on setting

You just have to choose.

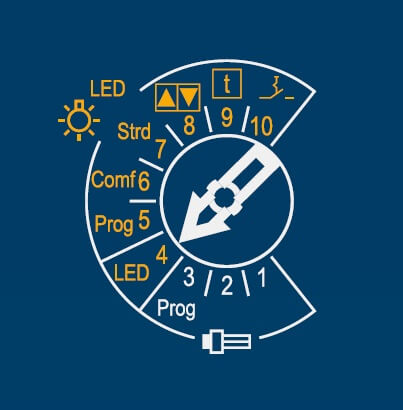

The THEBEN DIMAX 534 plus universal dimmer is fully LED compatible and has a choice of settings to adapt to this technology.

The minimum brightness of low-load LED lamps can be adjusted using potentiometers and rotary switches. Even the type of control can be selected to be phase-locked or flicker-angle controlled, so it can be used with virtually any LED light source without any problems.

Up to date with KNX

Dimming curves can be updated

Theben's KNX universal dimming actuators can do even more: with the ETS programming software, not only can you select the pre-stored dimming curve for a given LED lamp, which ensures stepless and uniform dimming, but you can also update it at any time as soon as the light source manufacturer issues an update. Or a completely new luminaire can be implemented, thus guaranteeing the durability of the present value of the investment.